ZEISS ATOS Q Industrial 3D Scanner

Compact, adaptable, and accurate—the ATOS Q is built for the demands of your shop floor. This versatile 3D scanner is engineered for complex measurement and inspection tasks across a wide range of industries, delivering high-precision results.

- Quality starts with Q: It delivers fully traceable measurement results even under harsh conditions.

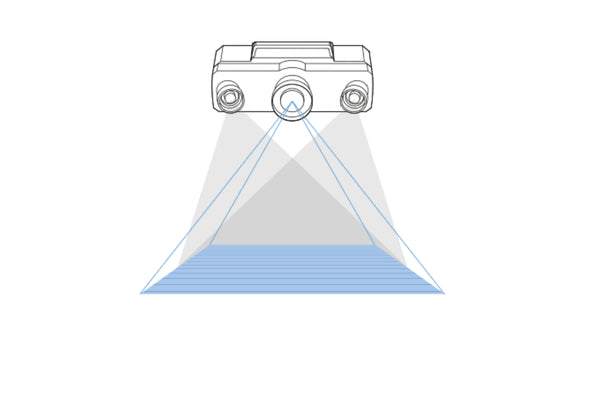

- Blue Light Equalizer: Enables high-speed fringe projection and is so powerful that short measuring times can be achieved even on challenging surfaces.

- Multiple Measuring Volumes: Ensures high-precision measurements of small to medium-sized parts using only one system with interchangeable lenses.

|

🗓 Instantly Book a Web Demo With Us

We can give you a personalized experience without ever leaving your desk. Demo time will be confirmed immediately after you submit your request. Book using our calendar.

|

Technical Specifications

The ATOS Q 3D scanner is available in the 12M and 8M versions. The sensors capture up to 2 × 12 million or 2 × 8 million coordinate points during 3D scanning. The precision, the resolution and the size of the measuring area are freely definable.

ATOS Q 8M:

- Light Source: LED

- Measuring area (mm²): 100 x 70 – 500 x 370

- Points per scan: 8 million

- Point distance: 0.04 – 0.15 mm

- Working distance: 490 mm

- Measuring volumes: 100, 170, 270, 350, 500

- Operating system: Windows 10

ATOS Q 12M:

- Light Source: LED

- Measuring area (mm²): 100 x 70 – 500 x 370

- Points per scan: 12 million

- Point distance: 0.03 – 0.12 mm

- Working distance: 490 mm

- Measuring volumes: 100, 170, 270, 350, 500

- Operating system: Windows 10

Designed as a versatile 3D scanner for complex measurement and inspection tasks, ATOS Q meets high metrological demands across many industries. It’s reliable, adaptable to various applications thanks to its flexible field of view, and a compact design for maximum portability.

What is ATOS Q 3D Scanner?

ATOS Q is a versatile industrial 3D scanner, ideal for a wide range of applications thanks to its flexible field of view, or measuring area. It combines many of the advanced features found in ZEISS' high-end automated systems, while its lightweight design ensures easy portability—offering users both convenience and versatility.

The system is very flexible with interchangeable lenses to fit many different use cases. It captures details in an accurate way and is suited for more demanding measurement tasks.

ATOS Q's lightweight design makes it easy to transport from one location to another, providing users with added convenience and flexibility.

Why Choose ATOS Q?

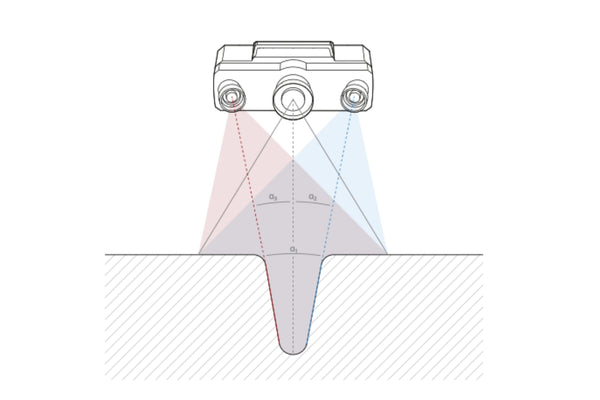

Triple Scan Principle For Fast Coverage

Blue Light Equalizer for Lowest Noise Level

Portable Measurement System

Reliable – a Real ATOS Sensor

Making Quality Visible

ATOS Q operates with ZEISS INSPECT, the well-established standard in 3D metrology and part of the ZEISS Quality Suite.

Use this all-in-one solution for simple or complex inspection tasks throughout your entire inspection process—from scanning, mesh editing and CAD import to trend analyses, digital assembly or proprietary inspection. A software to simplify and speed up your workflow.

Learn MoreGet More with ZEISS INSPECT — Pro Line

ZEISS INSPECT – Pro Line offers a comprehensive suite of advanced features for precise scanning and inspection, delivering reliable results even for the most complex tasks and challenging surfaces.

Enjoy enhanced functionality and intuitive operation for an even more streamlined workflow. Utilize live tracking and feature back projection for highly precise component positioning in any environment, and expand your capabilities by combining scanning with probing using a touch probe.

Flexible 3D Scanner for Different Industry Applications

ATOS Q 3D scanner is built for complex measurement and inspection tasks. Its interchangeable lenses deliver high-precision measurements, while the fixed camera position makes it simple to switch between the smallest and largest measuring volumes.

Quality Assurance for Additively Manufactured Parts

ATOS Q plays a key role in additive manufacturing by capturing full-field data, which reflects the impact of machining and surface finishing on 3D-printed parts. The system reduces iterations, improves process control, and boosts product quality.

Accelerating the product development and launch phase.

Quality Assurance of Plastic Parts

ATOS Q optical 3D scanner quickly captures full-field measurement data of plastic parts. ATOS Q ensures highly accurate and repeatable measurements, even capturing the smallest details for precise evaluations—such as tool geometry corrections (sink marks, warpage, shrinkage) and machine/process parameters. The system also supports production control, reducing scrap and rework, while enabling trend analysis through scan data of multiple parts.

Speeding up all phases in:

- injection molding

- blow molding

- thermoforming processes

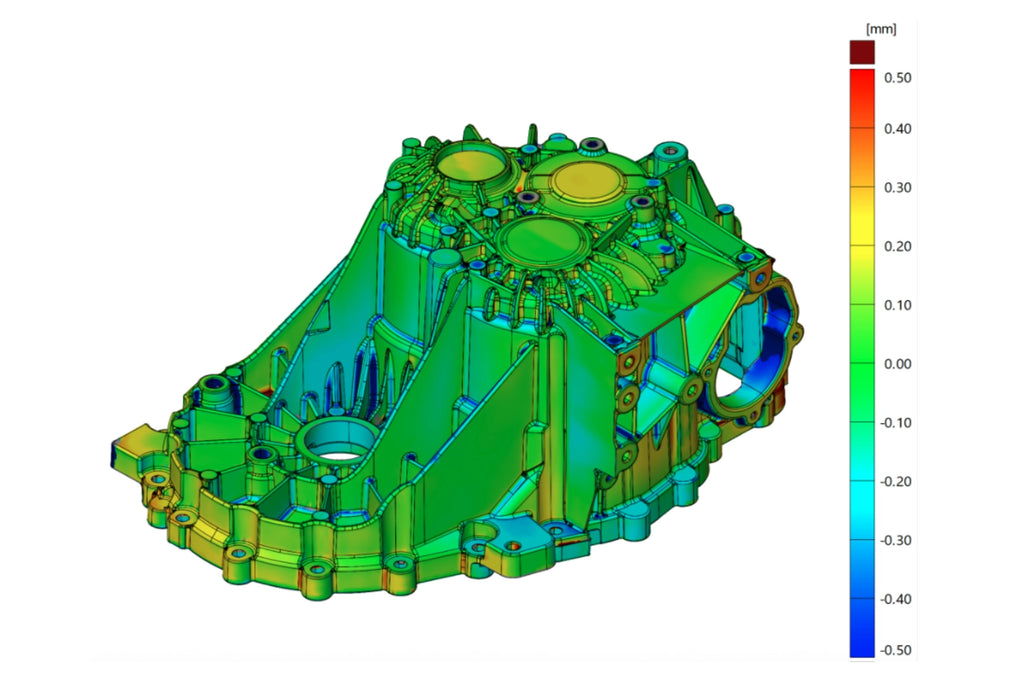

Quality Assurance of Casted Parts

ATOS Q is ideal for sand, pressure die, and investment casting processes, ensuring consistent quality assurance. During tool try-out, it digitizes the full surface of cast parts, allowing for deviation analysis by comparing full-field measurements to CAD data, which speeds up mold corrections. Deviation analysis, section inspections, feature location checks, and full GD&T analysis are easily done using ZEISS INSPECT software.

Optimizing processes in:

- sand casting

- pressure die casting

- investment casting

Quality Assurance of Sheet Metal Parts

As the demand for high-quality sheet metal parts continues to rise, so do the requirements for functionality and safety. Additionally, the ability to develop and launch products quickly is a key competitive advantage. This makes a fast, efficient measuring system for checking product shapes and quality essential.

ATOS Q is a great solution for optimizing metal forming (punching, bending, drawing and pressing) process chains.

ScanPort for Easy Automation

Compact and flexible, ZEISS ScanPort accessory delivers automation wherever you need it.

3-Axis for Automated 3D Scanning

ZEISS ScanPort is a complete solution for 3-axis automation with just one click. It is a mobile and flexible semi-automated system that delivers metrologically flawless data. Operated with ZEISS INSPECT, ZEISS ScanPort is your all-in-one solution to capture all details of your parts.

* This accessory is compatible with ATOS Q and GOM Scan 1 3D scanners.

Reproduce Your Scan in One Go

ZEISS ScanPort is a powerful tool designed for the repeated inspection of complex, similar parts (multi-part scanning). With its motion replay feature, you can repeat the exact same measurement process with a single click—automatically updating the inspection for each new part. It also allows you to compare deviations across all scanned parts, making it easy to spot trends and variations quickly.

- High repeatability and accuracy

- Customizable template-based 3D scanning

3D Scanning for Parts Manufacturing Inspection

Discover how you can reimagine your quality inspection workflow—delivering greater accuracy in significantly less time.

Be Confident in Every Inspection with 3D Digitization

Even the smallest imperfection can compromise performance, lead to costly recalls, or damage your reputation. Conventional inspection methods are slow at taking measurements. They often overlook minute defects that are difficult to catch.

Ditch the complexity to get better and more accurate results. With 3D scanning, you can capture measurements of a physical object with exceptional accuracy! Instantly compare 3D scanned data of a part against your CAD models to detect even the slightest deviations—before they become bigger problems.

Book a Live Web Demo with Us

Hassle-Free Booking

Scheduling a demo with us is fast and easy. Pick a day and time that works for you and press confirm—that’s it. You’re all set! We’ll email you the meeting instructions and see you there. 👋

We’ll walk you through everything you want to know about 3D scanning and show you how this technology can transform the way you work for your metrology needs.

Schedule a DemoFAQ

Common questions to GOM Scan 1 3D scanner.

What are the technical specifications of the ATOS Q?

ATOS Q has two models. You can find the full technical specification in the brochure.

Can I get a demo for this 3D scanner?

Yes! You can Instantly Book a Web Demo With Us. We can give you a personalized tour without ever leaving your desk. Demo time will be confirmed immediately after you submit your request. Book using our calendar.

Can I get the price for the ATOS Q?

Yes, most certainly! Please fill out our request a quote form and we'll have our team contact you shortly. Please contact us to see if you qualify for any special discounts or promotions.