Geomagic Control X (Professional License & Upgrade Options)

Geomagic Control X 3D Inspection and Metrology Software - Ensuring Quality Everywhere

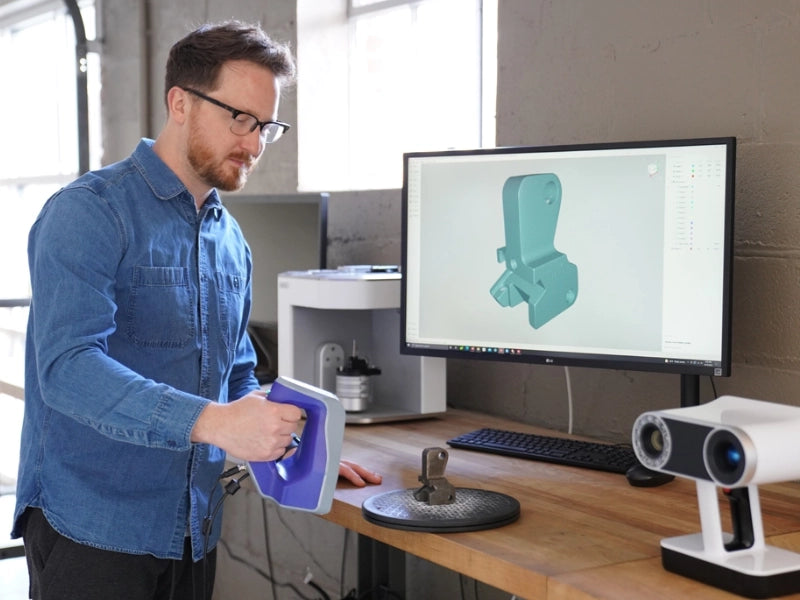

Inspection made simpler. Capture and automate the processing of data from 3D scanners and other devices. Measure, understand, and communicate inspection results with next to no human interaction.

- 3D scanning and inspecting parts with Control X is up to 7x faster than with a CMM.

- Control X customers report up to 80% lower inspection costs based on time and labor savings.

This listing is for Geomagic Control X one-time purchase license

If you require a different version of Geomagic Control X including annual subscription license, please visit here.

Brochures

Licensing Options

- Online Activation License: Node lock license on a single computer. You can activate or deactivate licenses to move from machine to machine. Internet access is required for this license type. This is the default license type for Geomagic products.

- USB Dongle: One license on the network used on any computer at one time. A physical license key that can license the software. To use this licensing option, insert your USB dongle into an available USB port on your machine then launch the application.

- Network License (Floating): One license on the network used on any computer at one time. This is an enterprise solution for users wishing to control the distribution of their purchased licenses across a network.

Where Can I Find the Education License Listing?

Looking for the Education License for Geomagic Control X? You can find it here.

Got Questions?

Please feel free to contact us with your questions by filling out our contact form.

Geomagic Control X is a flexible and reliable 3D metrology solution for inspection and verification of manufactured parts from design to production.

Why Use Geomagic Control X?

Geomagic Control X focuses on helping your organization measure more parts, more often, and in more places. Empower your staff and stakeholders to improve quality at every step of your design and manufacturing processes. Significantly improve the quality of manufactured parts and assemblies using powerful tools inside Control X to compare 3D scanner data with CAD models or a golden standard. Build inspections with total accountability and traceability throughout the entire process.

- Agile: Integrate with any scanner or PCMM arm.

- Fast: Collect and analyze huge data sets, 7x faster than CMMs.

- Simple: Automate repetitive and complex tasks easily to get results with little or no training

What Can You Do With Geomagic Control X?

With extensive Geometric Dimensioning & Tolerancing (GD&T) tools, you can analyze size, form, orientation, and location of features according to the ASME Y14.5M standard using Geomagic Control X. Intuitively dimension and constrain features directly from CAD, or import PMI/MBD enabled models for dramatic improvements in inspection process setup efficiency.

Hardware Agnostic

Built On A CAD Kernel

Simple To Use Automation Tools

Intelligent Measurement And Feature Recognition

Streamline Production

Geomagic Control X Highlights

Bring the power of 3D scan-based inspection to more people in more places.

Device Integration

Drive your 3D scanner or PCMM directly inside Control X or work with data from any device.

Automation

Customize and maximize inspection throughput with Visual Scripting and Automation Server capabilities.

Airfoil Analysis

Quickly and intuitively gather profile measurements, including twist analysis, for turbines, blisks, blades and more.

Deviation Location

Scan, analyze, and report surface defects and variations.

Annotations & Dimensioning

Use customizable annotations, CAD-aware dimensioning, PMI support and comprehensive GD&T callouts.

Ensure Perfect CAD with the Accuracy Analyzer

Geomagic Design X's accuracy analyzer is a real-time patented analysis tool to directly compare

your 3D models to the scan data so you can create CAD models as accurate as possible.

Applications

- Aerospace: Recreate blades and blisks with dedicated blade geometry tools.

- Automotive: Fast and accurate volumetric reporting, perfect for costing and planning additive production of heat exchangers.

- Healthcare: Automate a set inspection routine, even when the reference geometry changes from patient to patient.

- Electronics: Accurately report out surface area data for electro-plating components.

- Mining: Wear analysis and replacement prediction of important components such as ball mills.

- Research: Measurement of deformation of material exposed to external events such as explosions or radiation.

Large-Scale 3D Data Processing

If you are curious about how large-scale 3D scanning and processing can transform the way you work, here's a webinar for you. Our team captured 1.2 billion data points easily using the Artec Ray II Lidar 3D scanner. A powerful hardware needs an equivalent software that can handle the massive data sets and ensure smooth processing. We're able to accomplish that with Geomagic Design X + Control X. Check out our webinar preview and watch the full episode to see how this powerful solution can work for you.

Watch the full webinarBook a Live Web Demo with Us

Hassle-Free Booking

Scheduling a demo with us is fast and easy. Pick a day and time that works for you and press confirm—that’s it. You’re all set! We’ll email you the meeting instructions and see you there. 👋

We’ll walk you through everything you want to know about 3D scanning and show you how this technology can transform the way you work.

Schedule a Demo